Process Equipment Air Slides Manufacturers – AIR SLIDES

Ashoka one of the leading Process Equipment Air Slides Manufacturers, fir Slides (Fluid Slide) are used for pneumatic handling of fine, dry material like cement, ash, dusts and powder etc. Fluid slides are one the most economical mode of transport, which need very less maintenance. Air slides are basically aeration conveyors which carry fines through a current of low pressure air passed through a porous fabric that is tightly spread across the split face of the rectangular trough.

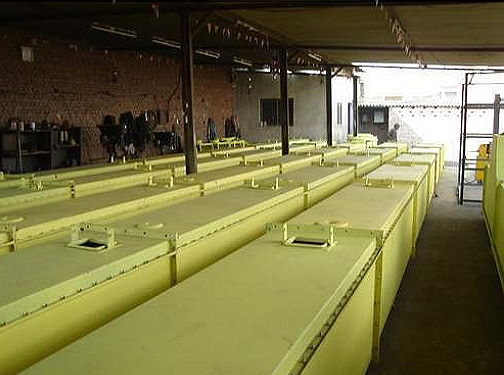

Process Equipment Air Slides Manufacturers are designed with 2 chambers- upper & lower. The upper chamber is used to carry the material and the lower chamber is used to aerate the fabric. They consist of special synthetic fabric, high-pressure fan and manual butterfly valves for control of air. Open air slides are also manufacturers, designed and supplied as per process requirement.

Process Equipment Air Slides Manufacturers |

| AIR SLIDES |

Used for pneumatic handling of fine, dry material like cement, ash, dusts and powder etc. Ashoka India Manufacturers Air Slides are one the most economical mode of transport, which need very less maintenance. Air slides are basically aeration conveyors which carry fines through a current of low pressure air passed through a porous fabric that is tightly spread across the split face of the rectangular trough.Fluid slides are designed with 2 chambers- upper & lower. The upper chamber is used to carry the material and the lower chamber is used to aerate the fabric. Ashoka India Manufacturers these fluid slides consist of special synthetic fabric, high-pressure fan and manual butterfly valves for control of air. Open air slides are also designed and supplied as per process requirement. |

|

Common industrial applications include material handling in cement plants, chemical and mineral processing industry, bulk loading of fine materials such as on ships etc. Some key features of air slides supplied by ASHOKA are :

They are used for pneumatic handling of fine, dry material handling equipment like cement, ash, dusts and powder etc. They are one the most economical mode of transport, which need very less maintenance. Basically aeration conveyors which carry fines through a current of low pressure air passed through a porous fabric that is tightly spread across the split face of the rectangular trough. They are designed with 2 chambers- upper & lower. The upper chamber is used to carry the material and the lower chamber is used to aerate the fabric. These consist of special synthetic fabric, high-pressure fan and manual butterfly valves for control of air. Designed and supplied as per process requirement. Process Equipment Air Slides Manufacturers. |

Belt conveyors are used to convey material for handling equipment horizontally as well as with high inclinations and for long distances in thousands of meters. Specially processed (heat resistant if required) rubber belts are over a series of idlers and rollers for continual movement and transport. Ashoka India Material Handling Equipment Manufacturers, gear reducer and motorized drive is located at one end of the conveyor.

Conveyors are suitable for belt widths up to 1,500 mm. and capable of handling materials at the rate of 500TPH. Idlers are impact type, toughing, garland idlers which give higher guaranteed output. Pulley is suitable for conveyors of belt width ranging from 300 mm. to 1500 mm. Belts are procured from renowned manufactures, Some key features of belt conveyors supplied by ASHOKA are-

- Assembled with Heavy duty steel structures.

- Steel inclinations available

- Heavy duty spherical roller bearings

- Low power consumption through planetary reduction gear box

Some common materials handled include- coal and mineral, mineral ores, Lime, sand, gypsum, cement, clinker, fertilizer, bag handling etc.